PRODUCT

Deep groove ball bearings are suitable for high speed operation, are very durable and do not require frequent maintenance. This type of bearing has a small friction coefficient, used in precision instruments, low-noise motors, automobiles, motorcycles and general machinery and other industries, it is the most widely used type of bearing in the machinery industry. It mainly bears radial load, and can also bear a certain amount of axial load. The most common deep groove ball series are 6000 series, 6200 series, 6300 series, 6400 series.

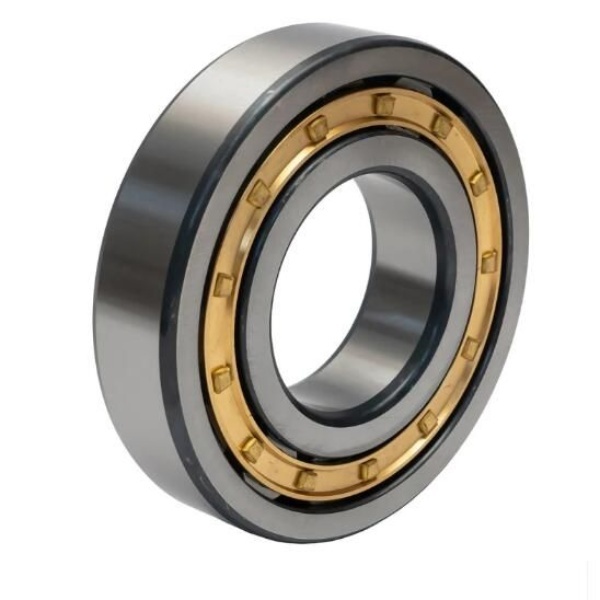

It consists of an outer ring, an inner ring, a set of steel balls and a set of cages. It mainly bears pure radial loads, but also can bear joint loads. We have three seal types:ZZ type、2RS type、Open type.

Deep groove ball bearings are suitable for high speed operation and are very durable. This type of bearing has a small friction coefficient and is used in precision instruments, low-noise motors, automobiles, motorcycles and general machinery and other industries.

The deep groove ball structure is also divided into two types: sealed and open. The open type means that the bearing does not have a sealed structure. The sealed deep groove ball is divided into dust-proof seal and oil-proof seal. The material of the dust-proof sealing cover is stamped steel plate, which only serves to prevent dust from entering the bearing raceway. The oil-proof type is a contact oil seal, which can effectively prevent the grease in the bearing from overflowing.

Brass cages have good processing properties and formability, making them a commonly used bearing cage material. The brass cage ensures that the bearing will not deform or fall off when rotating at high speed, and there will be no complex friction between the rolling elements and the cage, making the bearing work more smoothly.

This type of bearing has small friction coefficient, high rotational speed, simple structure, low manufacturing cost, and relatively easy to achieve high precision. It mainly bears radial load, and can also bear a certain amount of axial load. Compared with other types of deep groove ball bearings of the same size and size, this type of bearing has a small friction coefficient and a high limit speed. However, it is not shock resistant and not suitable for heavy loads.

Miniature bearings refer to various types of bearings in the metric series, with an outer diameter less than 9mm; in the imperial series, with an outer diameter less than 9.525mm! The main materials include carbon steel, bearing steel, stainless steel, plastic, ceramics, etc. The minimum inner diameter can be 0.6mm, and generally the inner diameter is 1mm.

Thickened deep groove ball bearings

Deep groove ball bearings are suitable for high-speed and even extremely high-speed operation, and are very durable and do not require frequent maintenance. This type of bearing has small friction coefficient, high limit speed, and various size ranges and forms. It is used in industries such as precision instruments, low-noise motors, automobiles, motorcycles, and general machinery. It is the most widely used type of bearing in the machinery industry. It mainly bears radial load and can also bear a certain amount of axial load.

Ordinary deep groove ball bearings are easy to rust when used for a long time or in places with a lot of water vapor. The friction of the steel balls of ordinary deep groove ball bearings has a great influence on the speed, making it difficult to meet high speed requirements. - Speed app.

Flange deep groove ball bearings are used in a wide range of applications, from printers to monitors.