Tapered Roller Bearing

CATEGORY:

Tapered Roller Bearings

Product Description

Keywords:

Tapered Roller Bearing

Tapered roller bearings are separated bearings, and the inner and outer rings of the bearings are equipped with tapered raceways. This kind of bearing is divided into single row, double row and four row tapered roller bearings and other different structural types according to the number of rows of rollers installed, and is widely used in automobile, rolling mill, mining, metallurgy, plastic machinery and other industries.

|

Product name |

Tapered Roller Bearing |

|

Bearings Feature |

1 Long life span 2 low rotation&impact resistance&vibration resistance |

|

Material |

Chrome Steel |

|

Bearing Package |

Pallet,wooden case,commercial packaging or as customers' requirement. |

|

Service |

OEM service provided |

|

Delivery time |

3-15 days depends on quantity needed |

Structure:

This type of bearing is equipped with a round platform roller, the roller by the inner ring of the large rim.

Single row bearings can bear radial load and unidirectional axial load, and double row bearings can bear radial load and bidirectional axial load.Suitable for bearing heavy load and shock load.

According to the different contact Angle (α), it can be divided into three types: small cone Angle, middle cone Angle and large cone Angle. The larger the contact Angle is, the greater the axial load capacity is.

Outer ring and inner assembly (inner ring and roller and cage assembly) can be separated for easy assembly and disassembly.

Bearings with rear auxiliary code "J" or "JR" have international interchangeability.

Common uses of tapered roller bearings

A tapered roller bearing is appropriate wherever a bearing must handle combination loads. One of the most common uses is maintaining axial balance, achieved with multiple tapered roller bearings along an axle or shaft. The tapered bearings will evenly distribute loads when adequately aligned, minimizing wear and tear on the components. With higher surface area, tapered roller bearings can distribute friction and heat from combination loads more efficiently than non-tapered rollers (which are more efficient than tapered bearings only with the most straightforward non-combination forces). This reduced friction increases the rotational speed of interfacing parts and makes tapered roller bearings ideal for use in:

- Engines

- Motors

- Gearboxes (especially those with helical gears)

- Wheels & axles

- Turbines & propellers

This equipment must combine many different angles and utilize them to drive motors, driveshafts, and other rotational components.

OUR FACTORY

We specialize in providing forklift bearings, deep groove ball bearings, self-aligning ball bearings, self-aligning roller bearings, cylindrical roller bearings, tapered roller bearings, wheel hub bearings, agricultural machinery bearings, etc.

PRODUCT TESTING

We use advanced equipment to conduct strict quality inspection to ensure product quality.

PACKING AND DELIVERY

Sufficient stock for quick shipment.

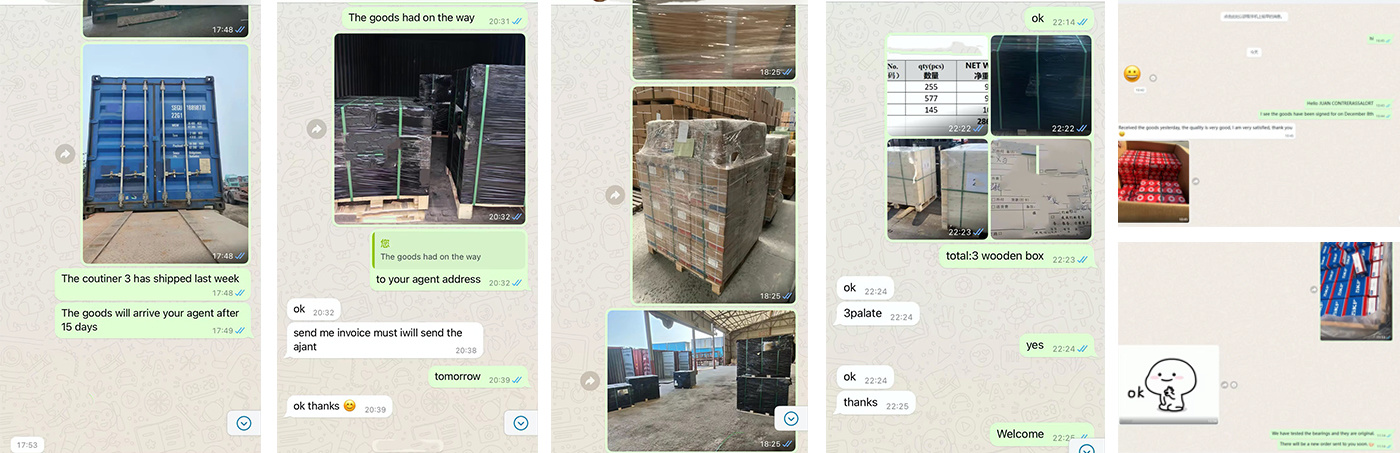

CUSTOMER CHAT

Our professional service team provides you with the best service experience.

THE ADVANTAGES OF CHOOSING AIFULE

Whether you require standard bearing solutions or customized designs, we are here to meet your needs and support your success. Partner with us, and experience the Aifule difference in precision bearing solutions.

SPECIAL DISCOUNTS

QUALITY ASSURANCE

PROFESSIONAL SERVICES

VERY FAST SHIPPING

FAQ

RELATED PRODUCTS

MESSAGE